The colors you see on screen may not always match what comes out of the printer. That’s why understanding vector color modes is essential for designers preparing artwork for print. At Mahi Digitizing, we help you navigate the technical side of vector color to ensure your final prints meet professional standards.

What Are Color Modes in Vector Design?

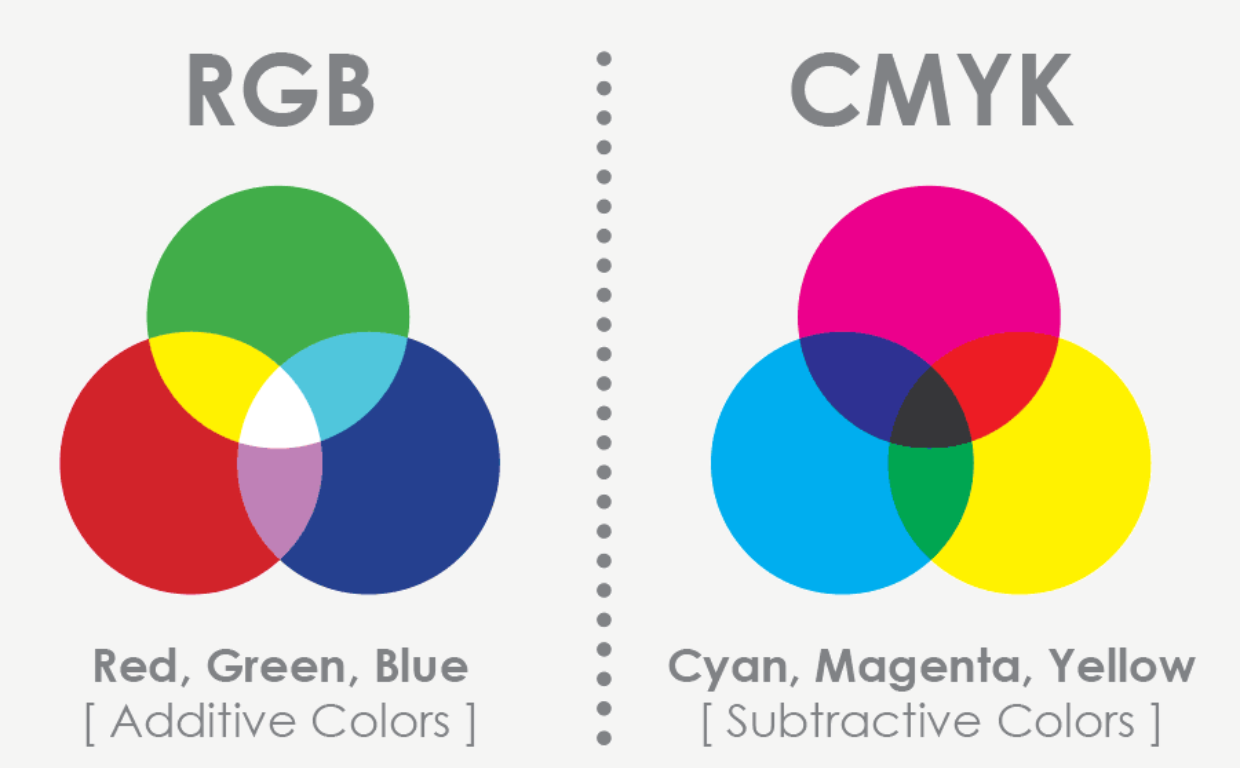

Color modes define how colors are created and displayed. In vector graphics, the two most common modes are RGB (Red, Green, Blue) and CMYK (Cyan, Magenta, Yellow, Black).

RGB is used for digital screens, while CMYK is the standard for physical printing. Choosing the wrong mode can lead to inaccurate or dull print results.

Designing in the correct mode from the start saves time, avoids costly misprints, and ensures color fidelity.

Our team at Mahi Digitizing ensures that your vector files are created with the appropriate mode based on your end-use goals.

We guide clients in converting files when switching from digital previews to final print outputs.

RGB vs. CMYK – What’s the Difference?

RGB color mode uses light to mix colors and is ideal for web, mobile, and screen-based viewing. It offers a wider color spectrum with vibrant, luminous shades.

CMYK, on the other hand, is pigment-based and used in ink printing. It works by layering inks to recreate images on paper, fabric, or packaging.

While RGB might appear more vivid, printers cannot reproduce those exact shades. This results in muted or altered colors when printed without proper conversion.

At Mahi Digitizing, we convert your RGB designs to CMYK using industry-standard tools, adjusting values to maintain the closest color match possible.

We recommend previewing artwork in CMYK before approving any print job to avoid surprises.

Why CMYK Is Preferred for Printing

Printers rely on CMYK inks, so providing CMYK-ready files is crucial for accurate color reproduction. This mode ensures that the colors you expect are the ones you get on physical materials.

Files in RGB can shift in tone or brightness once printed, especially on textured or colored stock.

CMYK also gives printers more control over ink balance and color consistency across large print runs.

From packaging and t-shirts to stickers and tags, CMYK files reduce revision cycles and ensure production efficiency.

That’s why we set up your vector files in CMYK from the beginning for all print-intended projects.

Best Practices for Color Mode Selection

- Use RGB: When your artwork is for websites, social media, or digital displays.

- Use CMYK: For physical items like business cards, brochures, apparel, and packaging.

- Convert early: Always switch to CMYK before finalizing colors for print. This helps you see realistic color output.

- Proof with samples: Ask your print provider for a proof to verify how the converted colors will appear.

- Avoid over-saturation: Extremely bright RGB colors may not be printable. Adjust or tone them down in CMYK mode.

Mahi Digitizing offers color consultations and print previews to ensure your designs translate beautifully across all materials.

Common Mistakes to Avoid

One of the biggest mistakes in print production is submitting RGB files instead of CMYK. This leads to unpredictable results that can affect brand consistency.

Another issue is not using vector-compatible color palettes, which can cause problems with spot colors and gradients.

Failing to check how your design appears on different materials can also result in disappointment.

We help you avoid these errors by thoroughly reviewing each design and making necessary adjustments.

Our experienced team ensures your colors work across leather, fabric, vinyl, paper, and other print surfaces.

Choosing the Right Partner for Print-Ready Vector Files

At Mahi Digitizing, we specialize in preparing vector artwork that’s optimized for both color mode and print technique. Whether it’s for screen printing, DTG, sublimation, or embroidery, our files are built for accuracy and impact.

We use Pantone matching, test swatches, and software previews to ensure your colors stay true throughout the process.

Our support includes mode conversion, file cleanup, and design adaptation tailored to your print vendor’s specs.

Request a quote or contact us to get expert help with your next print project.