Sequin embroidery adds shimmer and style to apparel, but it demands careful planning during digitization. At Mahi Digitizing, we specialize in digitizing high-quality sequin designs that stitch cleanly, securely, and with maximum visual impact.

What Makes Sequin Embroidery Unique?

Unlike standard embroidery, sequin embroidery incorporates decorative sequins along with thread stitching. This combination enhances garments with sparkle and dimension, making it ideal for fashion, dancewear, and branding accents.

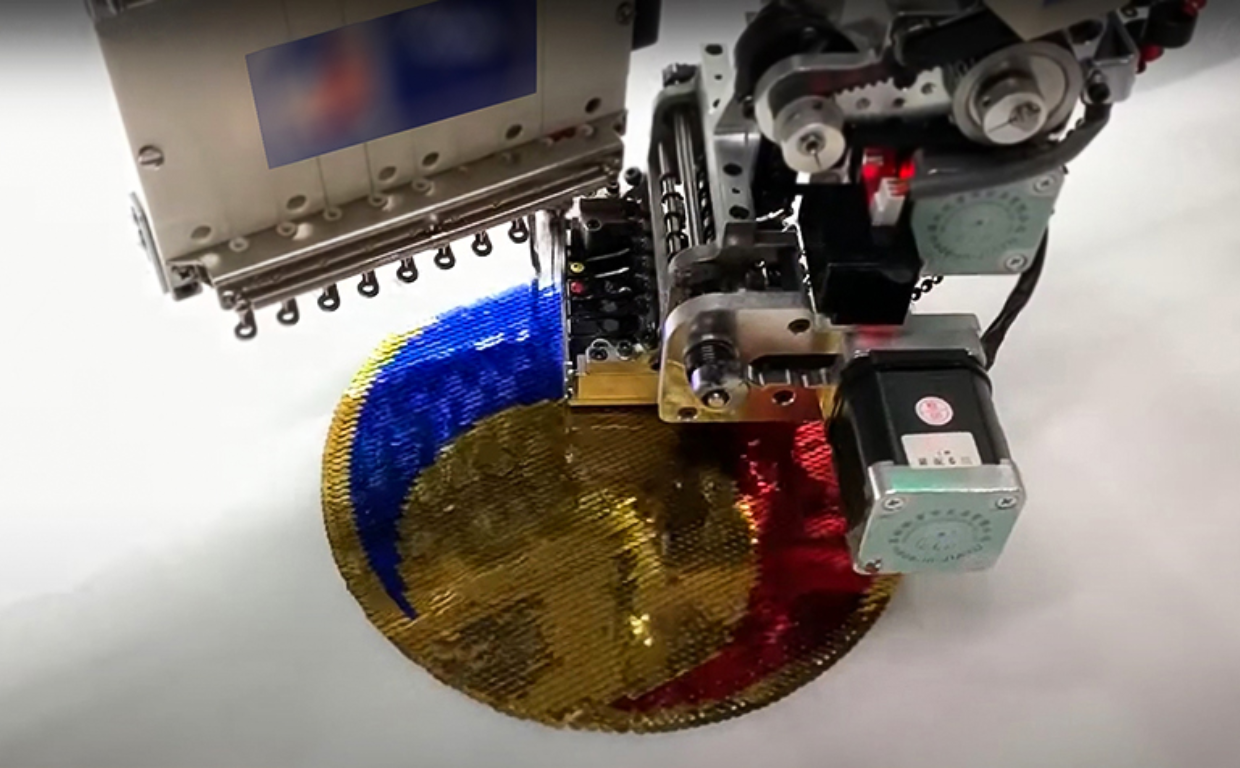

The technique involves embroidery machines equipped with sequin devices, which position and secure sequins with precision during the stitching process.

Sequin placement must follow specific guidelines to avoid overlap, ensure consistency, and align with the overall design.

Because sequins come in various sizes, shapes, and colors, digitizers must account for spacing and rotation settings to prevent tangling or stitching errors.

At Mahi Digitizing, we treat each design as a technical and creative challenge to ensure top-tier outcomes.

Choosing the Right Design for Sequins

Not every design is ideal for sequin embroidery. Simpler shapes, bold outlines, and open spaces tend to work best when sequins are involved.

It’s important to avoid small text, intricate lines, or tight curves that can crowd sequin placement and reduce clarity.

Designs that feature borders, floral motifs, or geometric patterns often pair well with sequins, especially in fashion-forward collections.

In many cases, combining thread-based stitching with sequin rows enhances both legibility and texture.

We guide our clients through this creative selection process to ensure sequin compatibility and optimal aesthetic appeal.

Essential Settings for Sequin Digitizing

Precision is key when digitizing sequins. The file must instruct the embroidery machine on sequin size, type, spacing, orientation, and stitch type.

Use consistent sequin size throughout each section to maintain uniformity. Changing sizes mid-design can lead to mechanical issues or uneven stitching.

Sequins can be stitched using lock stitches or zig-zag tacks. Lock stitches provide stronger holds, while zig-zags allow more flexibility.

Spacing must account for sequin width and prevent overlap. This ensures the sequins lie flat and reflect light properly.

We optimize these settings in every project to deliver machine-ready, production-proof sequin files.

Sequins and Fabric Compatibility

Not all fabrics support sequin embroidery. Lightweight or stretchy fabrics may pucker or become distorted during stitching due to the sequin tension and machine pressure.

Stiffer or medium-weight fabrics—such as denim, canvas, or jacket material—perform better and hold sequins more securely.

Stabilizers are crucial. We recommend firm backing to reduce shifting and distortion during the sequin application process.

Sequins can snag or reflect inconsistently on textured materials like fleece or velvet, so testing is vital before full production.

At Mahi Digitizing, we always test and simulate designs to ensure the embroidery and fabric pair perfectly.

Common Sequin Digitizing Mistakes to Avoid

- Too much density: Overcrowding sequins can jam machines or distort design flow.

- Improper anchoring: Weak tack stitches can lead to sequins falling off after washing or wear.

- Ignoring size restrictions: Using too-small designs may cause sequins to bunch or lose visual clarity.

- Unaligned starts: Incorrect start points result in misaligned sequin rows or gaps in stitching.

- No simulation check: Skipping preview runs increases error risk during production.

We apply proven workflows to prevent these issues and ensure professional, durable outcomes every time.

Software and File Format Recommendations

Sequin digitizing requires specialized software that supports sequin devices, such as Wilcom or Pulse. These tools provide control over sequence, rotation, and placement instructions.

Always use file formats supported by your embroidery machine model. Tajima (.DST) and Barudan (.DSB) are commonly used for sequin-compatible equipment.

When exporting designs, include notes on sequin size, color, and any machine-specific settings for clear communication with your production team.

We format each file based on your equipment specifications to minimize adjustments and errors during setup.

Our vector conversion and digitizing services include compatibility checks for all embroidery file types.

Testing and Adjusting for Flawless Results

Even the most detailed sequin embroidery file requires testing before going into mass production. Test runs reveal tension problems, placement shifts, or unbalanced sections.

Adjustments might include changes to stitch length, tack strength, or sequin overlap to enhance clarity and durability.

Always perform tests on the actual fabric and use the same machine model intended for final production.

Documenting the machine’s speed, needle type, and stabilizer used during testing also ensures repeatability and quality control.

We deliver stitch-ready files but also support our clients in refining outcomes with expert insights and post-digitizing guidance.

Work with Mahi Digitizing for Expert Sequin Embroidery Files

Sequin embroidery requires more than software—it demands experience and a clear understanding of fabric behavior, machine mechanics, and artistic balance.

At Mahi Digitizing, we create production-ready files for both fashion and commercial use, helping brands achieve brilliance with every sparkle.

Our team consults on sequin style, placement, and design refinement to maximize impact and ensure smooth stitching.

From dance costumes to logo highlights, we know how to combine sequin embroidery with branding or style themes.

Request a quote or contact us today to elevate your embroidery with sparkle and precision.