Tackle twill embroidery combines bold visuals with long-lasting quality, making it a popular choice for jerseys, varsity jackets, and sports gear. At Mahi Digitizing, we know the materials and techniques that bring out the best in every design.

What Makes Tackle Twill Unique?

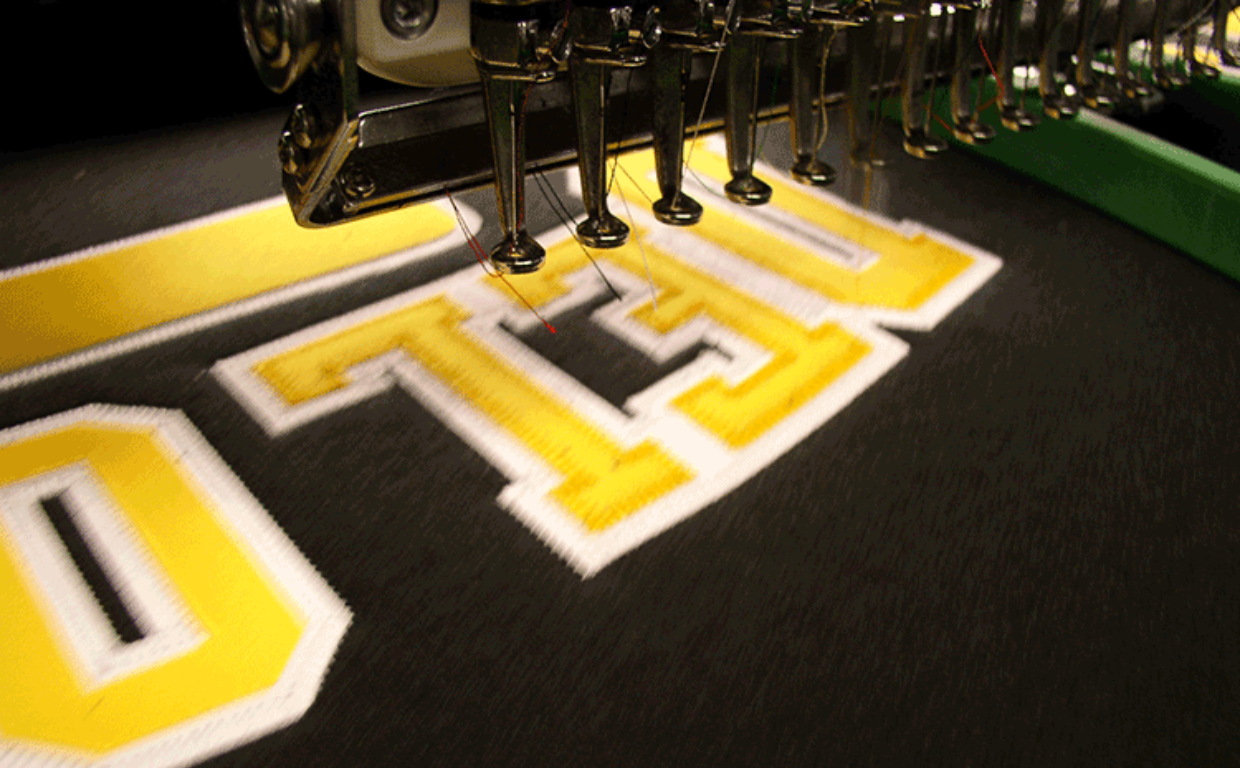

Tackle twill involves cutting letters or shapes from durable twill fabric and stitching them onto garments. This layered technique delivers bold, textured designs that are ideal for uniforms and team branding.

It offers a dimensional look with high durability, far surpassing standard flat embroidery in visibility and resistance to wear.

Moreover, the technique is versatile, allowing custom fonts, numbers, or logos to be applied to a wide range of clothing types.

With proper digitization and material selection, tackle twill can maintain its quality after repeated washing and use.

At Mahi Digitizing, we ensure every twill design is digitized for precision and ease of application.

Recommended Fabrics for Tackle Twill

Choosing the right base fabric is key to a clean application and long-lasting performance. Poly-twill is the most popular option, known for its tight weave and durability.

Felt can also be used, especially for vintage or varsity looks, offering a softer, classic texture. However, it’s less durable than poly-twill under heavy use.

Other suitable materials include cotton blends, nylon, and canvas—depending on the garment’s use and expected wear level.

Fabrics must hold the twill firmly and handle stitch density without puckering. We always assess your use case to match the perfect base.

Our experts at Mahi Digitizing provide guidance on material compatibility for every tackle twill order.

Selecting the Right Tackle Twill Material

The twill itself should be crisp, thick enough to hold its shape, and compatible with heat and adhesive backing. Poly-twill is available in various weights and finishes, giving you flexibility.

For high-impact sportswear, choose heavyweight twill for structure and longevity. For fashionwear, lighter options may suit better for comfort.

Colorfastness is also critical, especially for bold-colored twill used in team uniforms. We recommend pre-treated twill to reduce fading.

Backings should be chosen based on application method—heat-seal or sew-on—and whether the patch will face high movement or washing.

We offer customized material recommendations based on your design’s usage and appearance goals.

Top Stitching Techniques for Clean Results

The most common stitching methods include zigzag, satin, and running stitches. Zigzag stitching is widely used for its balance between durability and speed of application.

Satin stitch provides a more decorative finish, adding polish around letter edges, though it requires more machine time.

Running stitch is ideal for layering or outlining multiple elements in one design, especially in multi-color applications.

To avoid fraying, the edges of each twill piece must be securely stitched and, in many cases, heat-sealed before stitching.

We digitize tackle twill projects using stitch settings that maintain clean borders, structural integrity, and a professional finish.

Layering Techniques for Multi-Color Tackle Twill

Multi-color tackle twill requires precise alignment and smart layering. Each layer must be digitized separately, then stacked in the correct stitch order.

Overlap should be minimized to avoid fabric buildup while still ensuring full coverage and edge locking.

Color contrast is critical when layering—dark outlines around light letters offer maximum readability and impact.

Layered designs must maintain visual balance, especially for varsity-style text or complex logos.

At Mahi Digitizing, we specialize in multi-layer tackle twill digitizing that preserves design clarity and ensures seamless application.

Key Benefits of Tackle Twill with Proper Materials

- Durability: Ideal for high-wear gear like jerseys and jackets.

- Bold Appearance: Raised letters stand out on any garment.

- Versatile Textures: Choose felt for softness or twill for strength.

- Easy Branding: Reproducible for schools, teams, or merch lines.

- Customizable: Available in countless fonts, sizes, and layouts.

These advantages explain why tackle twill remains a top choice in both fashion and sportswear.

Mistakes to Avoid in Tackle Twill Applications

Improper digitizing can result in misaligned layers, loose edges, or excess stitch density that warps the base fabric.

Choosing incompatible fabrics may lead to puckering or poor patch adhesion over time.

Some designs contain elements that are too detailed for tackle twill—always simplify artwork for better results.

Skipping heat sealing or using poor-quality adhesives can reduce the patch’s lifespan significantly.

We prevent these issues by offering tailored recommendations and delivering perfectly digitized tackle twill files.

Why Choose Mahi Digitizing for Tackle Twill Projects?

At Mahi Digitizing, we provide expert digitizing services for clean, high-quality tackle twill embroidery across all types of garments.

Our team understands the stitching techniques, material selection, and layering that make each design stand out and stay durable over time.

We test stitch paths, edge locking, and thread patterns to ensure professional-grade results on jackets, hoodies, jerseys, and uniforms.

With fast turnaround and premium service, we help apparel brands, schools, and teams create bold tackle twill apparel that lasts.

Get a free quote or contact our team to start your custom tackle twill order today.