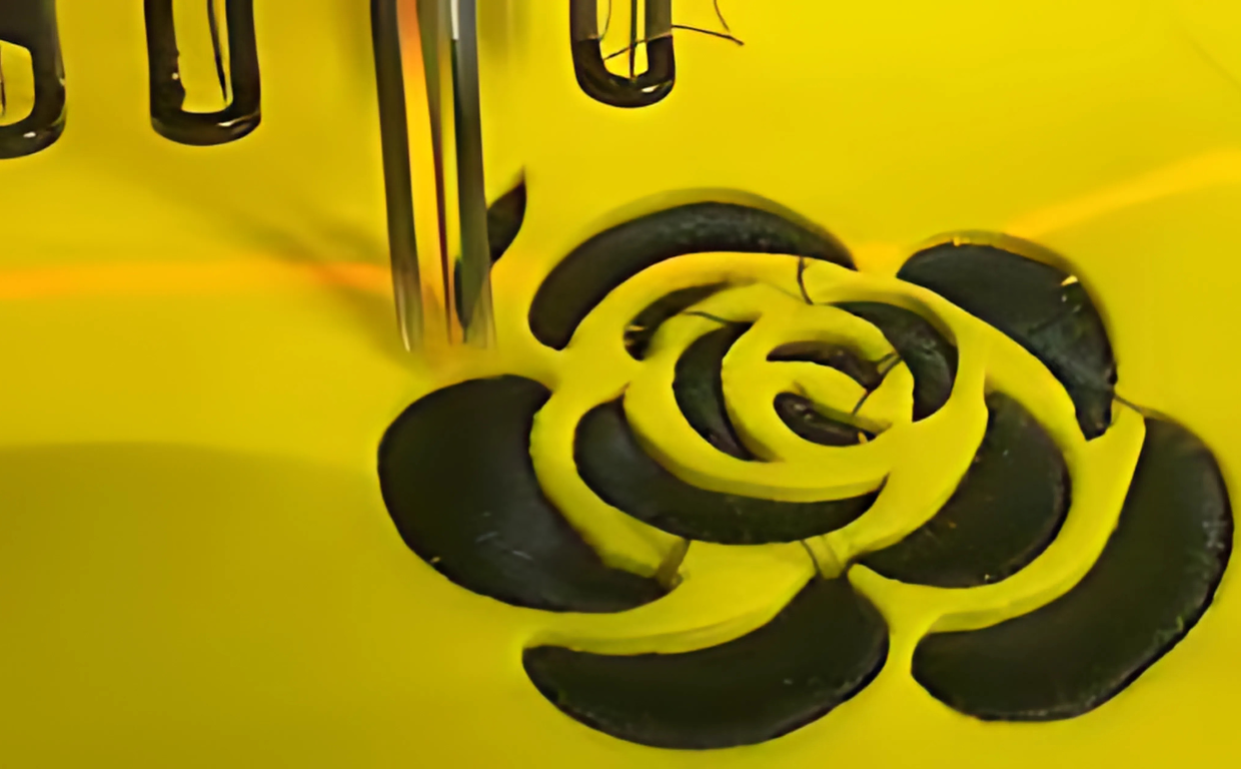

3D puff applique embroidery is bold, eye-catching, and often used for fashion, sportswear, and branding. However, it comes with technical challenges that can affect the final output. At Mahi Digitizing, we help embroidery professionals overcome these hurdles with precision digitizing and expert insights.

Managing Foam Thickness and Stability

One of the biggest challenges with 3D puff applique is managing foam thickness. If the foam is too thick, stitches may not penetrate properly, leading to a loose or uneven finish. Foam thickness needs to be aligned with fabric type and stitch density to maintain structure without damaging the material.

Low-quality foam tends to collapse during the embroidery process, affecting both appearance and durability. We use high-grade foam and test designs thoroughly at Mahi Digitizing to ensure clean outlines and raised effects. Understanding the role of foam in creating texture is key to solving the structural issues early in the design phase.

A balanced design with the right foam base leads to professional-quality applique every time.

Achieving Clean Edges Without Fraying

Frayed or uneven edges are common problems in puff applique. This usually results from poor digitizing or incompatible fabrics. Edge finishing must be done carefully to prevent unraveling, especially on curved or small design areas. Using satin or zigzag borders, backed with stabilizers, improves the finish and helps secure edges long term.

Our team at Mahi Digitizing pays special attention to edge cleanup in the digitizing process. Proper tension settings on the machine also reduce the chances of edge distortion or puckering.

Clean, sealed edges contribute significantly to a polished and durable puff applique result.

Stitch Density and Overlapping Issues

Incorrect stitch density can either crush the foam or fail to hold it in place, resulting in uneven or distorted designs. Too much overlap in stitch paths can cause thread breakage and misalignment, especially on dense fonts or logos.

Balancing underlay, stitch direction, and density allows the foam to retain its height while securing the design. We provide fine-tuned stitch setups to our clients to ensure clean execution every time. Test runs are essential to adjust overlapping and spacing for various types of foam and fabric.

With proper testing and adjustment, these issues can be completely avoided in final production.

Aligning Fabric Types with Applique

Not all fabrics are suitable for 3D puff applique. Stretchy or thin fabrics may deform during stitching or collapse after washing. Heavyweight materials like denim, twill, or structured caps offer the best base for foam-based applique. It’s critical to test fabric compatibility before beginning full production, especially for complex designs.

We consult with our clients on fabric recommendations as part of our digitizing service at Mahi Digitizing. Stabilizers, adhesives, or backing materials can also help reinforce delicate fabrics to support puff designs. Matching the right materials with design intent prevents structural failure and enhances end-user satisfaction.

Handling Complex Designs with Raised Effects

Designs with fine details or small fonts often pose a challenge for puff applique, as the foam limits tight curves and spacing. Simplifying design elements and scaling appropriately is necessary to maintain clarity when puffing.

We modify logos and vector art to ensure they can be executed with foam while maintaining branding consistency. Sometimes, only portions of a design should be puffed to balance visual impact and feasibility. Our experienced digitizers help strike this balance through smart layering and stitch planning.

A strategic approach allows even complex designs to look bold and professional with puff effects.

Post-Production Care and Shape Retention

Once the design is complete, the challenge shifts to maintaining the puff structure during handling, storage, and wear. Washing, folding, or compressing puff embroidery can distort or flatten the raised design over time. Proper washing techniques like cold cycles, inside-out washing, and air drying are essential for longevity.

At Mahi Digitizing, we advise customers on care instructions tailored to their fabric and design. Providing care labels or cards with each product helps clients preserve quality over time. Post-production care plays a major role in retaining visual appeal and performance of 3D puff applique.